Social responsibility

NORRES Schlauchtechnik has a long history of responsible behaviour towards the society we live in. We frequently participate in activities that benefit charitable organisations. We are extremely keen to support projects that help the socially disadvantaged, especially when they involve children. We also make an active contribution towards environmental protection.

NORRES Schlauchtechnik makes regular donations to “Noah's Ark”, a charity that describes itself as “a children’s hospice in the region and for the region”. The Ark’s concept, which is the only one of its kind anywhere in Germany, defines two main functions: to offer a haven for incurably ill children and to act as a short-term care centre for youngsters with severe disabilities. The aim is to assist the families concerned by providing professional care and respite for children and teenagers in the Noah's Ark centre. NORRES traditionally makes a donation to this deserving cause at Christmas.

At NORRES, all people are equal. All our staff benefit from the same opportunities. Their ethnic origin, religion, social background, age, sex or disabilities are considered to be irrelevant. NORRES maintains close links with a centre for handicapped people. Disabled staff carry out their work directly on the NORRES site and are therefore fully integrated in the life of the company.

The sustainable use of natural resources is firmly entrenched in NORRRES Schlauchtechnik's daily work processes. The move to our new “Am Stadthafen” facility coincided with extensive investments in eco-friendly production and HVAC technologies. Efficient insulation, double glazing, centrally controlled air conditioning with water chillers and production utilising heat recovery mean optimal protection for the environment. Since taking possession of the new and completely refurbished plant at the port of Gelsenkirchen in 2009, NORRES has succeeded in reducing the consumption of water, electricity and heating fuel dramatically – despite an almost fourfold increase in floor space.

Read the latest news about our social commitment and responsibility!

Hose designed for the plastics industry

The Plastic processing industry can be a complex process. During processing with granulates or powders are usually transported over long distances. The materials are transported through hose lines which must withstand extreme stress levels. The individual production process has to function efficiently with additional focus on the smoothness of the hose. Therefore choosing the right hose is an important factor.

Best product properties due to Pre-PUR®

Transport hoses, used as machine components in the plastics processing industry, are subjected to massive strains. In order to withstand this stresses during the application, the correct selection of the transport hose is important. Hose properties must require high abrasion resistance, therefore a high-grade material is required. NORRES Pre-PUR® hoses are made of premium polyurethane Pre-PUR®. The abrasion resistance of our Pre-PUR® Polyurethanes ist about two and a half to five times greater than many rubber raw materials and about three to four times higher than soft PVC materials.

Smooth interior und antistatic

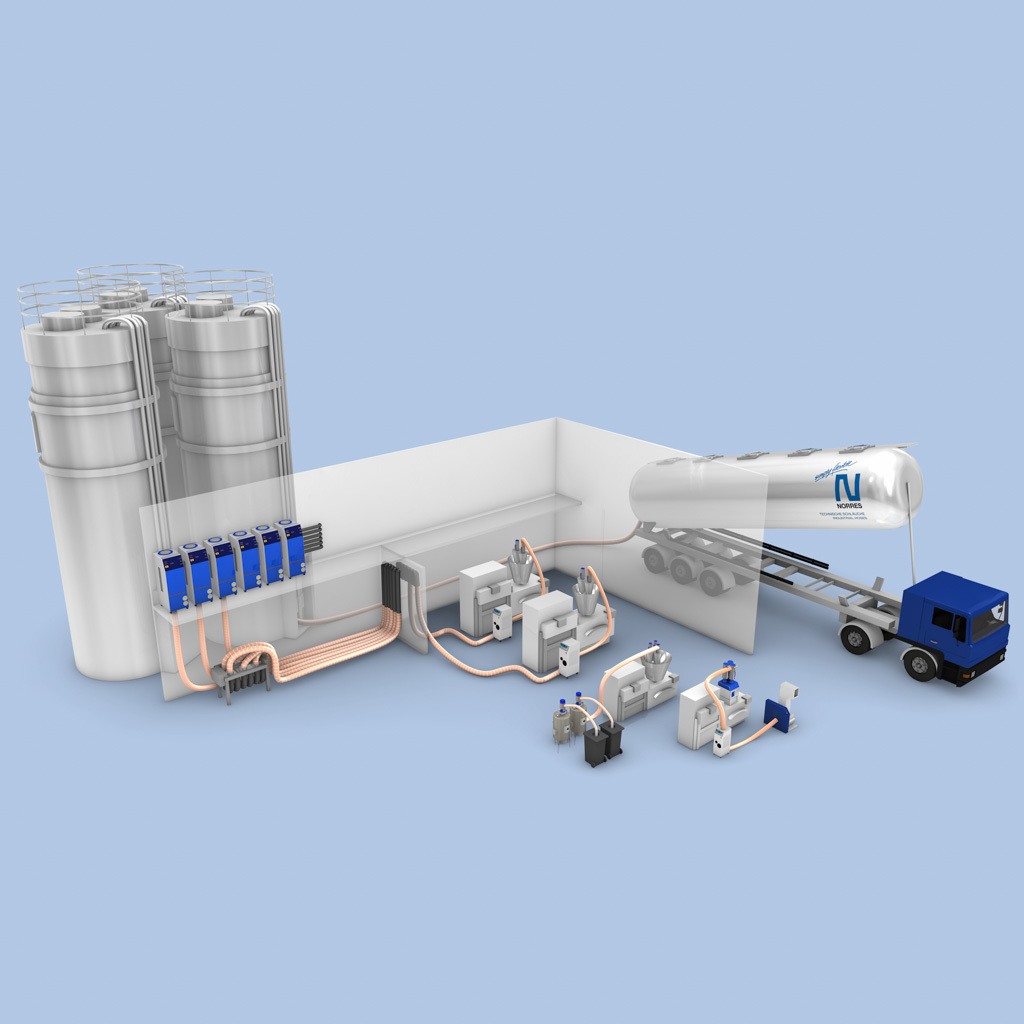

For applications in the specific field of plastics industry AIRDUC® PUR 355 AS and AIRDUC® PUR 356 AS has become very well established within our industry. The antistatic hose AIRDUC® PUR 356 AS is particularly suitable for loading and unloading of silos, silo vehicles and tankers.

AIRDUC® PUR 355 AS is particularly suitable for conveying in granulate conveying devices, extruders and injection moulding machines. Both types do have an interior smoothness that are optimised specifically to maximize flow. This process ensures a gentler material delivery. In addition both hose types have a permanently antistatic wall with electrical and surface resistance <10⁹ Ω. In accordance with ATEX 2014/34/EU and German TRGS 727 AIRDUC® PUR 355 AS and AIRDUC® PUR 356 AS are ideal for pneumatic transport of flammable dusts and bulk materials. They can also be used in a temperature range from -40°C to 90°C and short-term to 125°C.

Optimal branch products, combined with competent technical advice, NORRES creates added customer value. NORRES customers benefit from longer service lives, shorter downtimes and risks. This results in the buzzer also lower operating costs.

.svg)